Blog Layout

SCAFFOLDING SAFETY: 5 STEPS TO TAKE BEFORE ERECTING SCAFFOLDING

July 1, 2019

Everyday, dozens or even hundreds of people – friends and coworkers, beloved sons, daughters, fathers, and mothers – trust their lives and their livelihoods to safe and effective scaffolding solutions.

Scaffolding safety is of prime importance. By definition, these movable, adjustable, customizable construction tools can either prevent or cause dangerous conditions at the job site, depending on how well they function, and how they are used.

On-the-job hazards, close calls, or faulty equipment can have a dramatic impact on productivity and profit. Unsafe conditions not only reduce the enthusiasm of workers on the job site, but can also cause an accident to evolve into a costly lawsuit or workers’ compensation claim.

A holistic approach to scaffolding safety on the job site must take into account external threats, visitors, and the surrounding environment. Here are five steps to proactively create a safe job site before erecting scaffolding.

1. Get the Proper Equipment

Proper equipment is essential to set your job site up for success. Make sure to invest in high-quality Personal Protective Equipment (PPE), including:

- Hardhats with straps to prevent losing the hardhat while elevated.

- Gloves that allow dexterity while not sacrificing protection.

- High Vis apparel rather than vests that may get snagged on equipment during erecting and dismantling (E&D).

- Fall Protection such as retractable lifelines with steel cable vs synthetic lanyards as they are less prone to abrasion and possible fraying.

In addition, plan to take an extra step and provide a few extras to enhance safety, such as supplying:

- Lanyards for wrenches and hammers to prevent overhead tool loss and ‘Struck by’ incidents.

- Torque Wrenches vs. Standard Ratchets to prevent overstressing the equipment and thus reduce damage to structure components.

2. Evaluate Site Conditions

Ground conditions must be evaluated to ensure an adequate E&D process can proceed. However, geotechnical concerns like erosion potential or a high water table are not seen by the naked eye.

In addition, if you are working on industrial or multi-craft sites, coordinate with nearby trades before erection begins to ensure:

- No overhead work is being performed (e.g. cranes, manlifts, overhead structures or mezzanines, etc.). If so, guard against struck by hazards.

- No blasting is planned that may compromise E&D or structure post erection.

- No nearby excavations are happening, which could compromise soil or base

3. Create a Field Level Risk Assessment (FLRA)

A field level risk assessment (FLRA) is used to examine operational and procedural systems on a daily basis to identify hazards that may be necessary to protect workers at a site. By completing a FLRA prior to any work being done on site, possible risks and hazards are identified early and procedures can be put in place to suggest ways for controlling risks and keeping the site safe. It may include the use of some forms or checklists such as:

- Process of erection, which can minimize the hazards associated with the overall process

- Bracing plan

- Material Handling procedures

- Power lines

- Inclement weather

- Loading Capacity for occupants throughout E&D as well as use. For example, will the structure be sufficient for the intended purpose? Does the structure meet criteria where it would need to be ‘engineered’ vs erected by a competent person?

- Establish ‘Pass Line’ and methods of communication for materials to be hoisted and lowered

4. Create a Rescue Plan

A rescue plan should be mapped out for workers to refer to throughout the E&D process. Creating this before erecting scaffolding gives you time to add the proper materials to your inventory to have them on hand in the case of an emergency.

5. TRAIN, TRAIN, TRAIN your staff

When OSHA revised scaffolding safety standards in 1996, studies by the Bureau of Labor Statistics found that 25% of workers involved in scaffolding accidents

had not received safety training. As a manager, you can reduce the risk for your crew by conducting proper OSHA and equipment-specific safety training. OSHA training is designed to protect employees from common hazards such as falls, falling objects, structural instability, and overloading.

Beyond OSHA requirements, make sure to document all of the steps above and share it with your crew before erection begins. Once the job is underway, make sure to reevaluate these safety measures and continue to customize and adapt based on site needs.

Read this article

for additional scaffolding safety tips once your job site is active and underway.

You might also like

AT-PAC Blog

By Julio Black

•

February 17, 2025

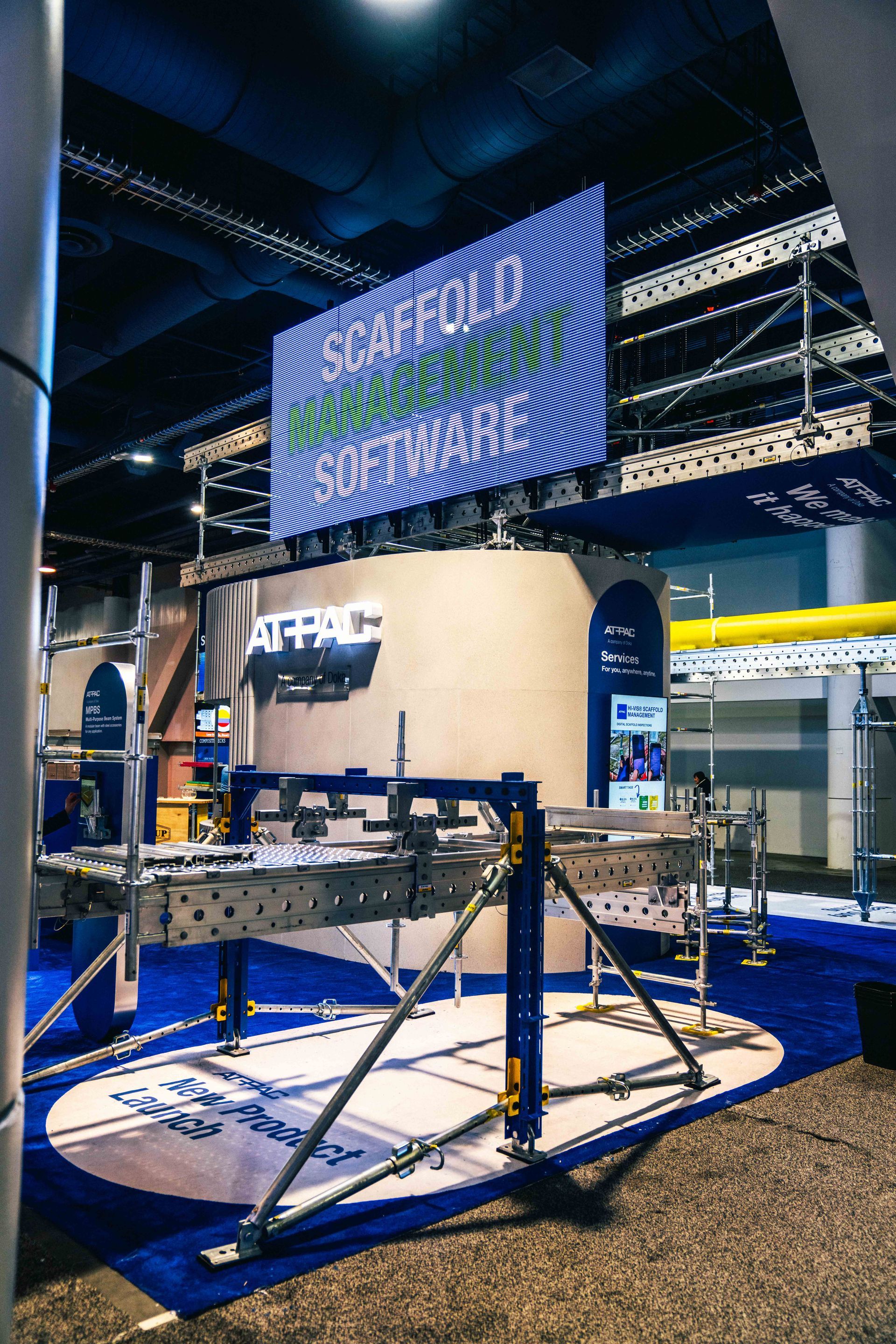

AT-PAC Unveils the Multi-Purpose Beam System (MPBS) at World of Concrete 2024 AT-PAC proudly launched its latest innovation, the Multi-Purpose Beam System (MPBS), at World of Concrete 2024, marking a significant milestone in scaffold technology. As a cutting-edge addition to AT-PAC’s proprietary Ringlock System Scaffold, the MPBS offers unparalleled versatility and efficiency, revolutionizing the way scaffold structures are designed and deployed. A Game-Changer for the Industry Designed to expand the capabilities of the Ringlock System, the MPBS provides a groundbreaking solution for a wide range of applications, including: Suspended Scaffold & Pipe Rack Scaffolds – Enabling safe and efficient suspended access solutions. Birdcages – Creating stable, large-scale work platforms. Large Span Bridging – Allowing for expansive scaffold spans with fewer components. Boiler Scaffolds – Meeting the unique needs of confined and high-heat environments. Cantilevers – Offering extended reach and accessibility. Innovative Design & Seamless Integration The MPBS system is engineered for simplicity and adaptability. At its core is a robust extruded aluminum beam, capable of supporting O-Type Ringlock Planks and an array of attachable steel accessories. With 6-inch (152.4mm) on-center attachment points along its length, the MPBS ensures maximum flexibility, making it suitable for diverse scaffolding applications. What sets the MPBS apart is its seamless integration into the Ringlock System, enhancing functionality while minimizing complexity. The ability to achieve larger spans than traditional methods reduces the overall number of components required, streamlining both installation time and labor costs.

By Julio Black

•

October 11, 2024

Atlanta, Georgia, USA AT-PAC is excited to announce the appointment of Mr. Allan Hazzard as Managing Director Canada. This appointment reinforces AT-PAC’s commitment to strengthening its local management structure to support the continued investment and future growth of our Canadian business. AT-PAC has operated its Canadian branch in Edmonton, Alberta since the year 2000, which has more recently operated alongside the U.S operations under a single North American regional structure. As part of Mr. Hazzard’s appointment, Canada will transition to its own local management structure to further support our recent and anticipated growth into new markets in Eastern & Western Canada. Josh Dundon, CEO shares “The appointment of Mr. Hazzard is a strategic step forward and will enable us to build off the existing talented team and our almost 25-year history in Canada to expand our presence and better service our customers in important markets across Canada”. Based in Calgary, Mr. Hazzard brings over 20 years of leadership experience, including the past decade in the modular building industry with WillScot and contributes a wealth of expertise in scaling businesses across Canada. His executive roles in commercial leadership and general management, both in Canada and the U.S., have equipped him with deep knowledge of asset intensive businesses servicing the industrial & commercial sectors. Mr. Hazzard added “I am truly honored to step into the role of Managing Director for AT-PAC Canada at such an exciting time in the company’s journey. Having spent much of my career in roles focused on scaling businesses across diverse markets, I am thrilled to now lead a talented team in driving AT-PAC’s continued growth and innovation in the Canadian market.” As Managing Director Canada, Mr. Hazzard will be responsible for leading and driving AT-PAC’s next phase of growth in Canada. This includes leading the existing Edmonton based team and implementing our Canada wide strategy ensuring a strong sales, commercial and operational structure to support our customers and continued growth into new markets.

By Julio Black

•

August 28, 2024

AT-PAC, a world leader in the supply of industrial scaffold products, is proud to announce its partnership with Habitat for Humanity. AT-PAC is thrilled to announce their partnership with Habitat for Humanity , a leading non-profit housing organization dedicated to creating and advocating for affordable homeownership. AT-PAC is partnering as a National Sponsor, contributing $100,000 of funding along with strong volunteer support to work towards the goal of affordable homeownership for all. This is a significant step towards enhancing AT-PAC’s corporate social responsibility efforts and will make a tangible impact on the lives of future Habitat homeowners, helping them realize their dream of owning a home and building a brighter future for their families . To kick off this collaboration, AT-PAC has committed to help as a “Roof Raiser” sponsor for Habitat for Humanity’s 2024 Jimmy and Rosalynn Carter Work Project in St. Paul, Minnesota, this October. This event will bring together an estimated 2,500 volunteers, community members, leaders, and future homeowners to build more than 35 new homes in five days! This annual, large-scale building event raises awareness of the critical need for affordable housing — the heart of Habitat’s mission. "This partnership reflects our shared commitment to building a better future, and I am excited about the positive changes we can achieve together" said Josh Dundon, CEO of AT-PAC. In addition, AT-PAC teams in both Atlanta and Houston will be participating in Habitat construction sites in their local communities, building alongside each other and future Habitat owners. Volunteers will see firsthand how affordable homeownership helps families build strength, stability, and self-reliance through shelter. About Habitat for Humanity Driven by the vision that everyone needs a decent place to live, Habitat for Humanity found its earliest inspirations as a grassroots movement on a community farm in South Georgia. Since its founding in 1976, the housing organization has since grown to become a leading global nonprofit working in local communities across all 50 states in the U.S., Puerto Rico, and more than 70 countries. Families and individuals in need of a hand up partner with Habitat for Humanity to build or improve a place they can call home. Habitat homeowners help build their own homes alongside volunteers and pay an affordable mortgage. Through financial support, volunteering or adding a voice to support affordable housing, everyone can help families achieve the strength, stability and self-reliance they need to build better lives for themselves. Through shelter, we empower. To learn more, visit habitat.org.

About AT-PAC

Locations

Careers

GLOBAL HQ

Atlantic Pacific Equipment LLC (AT-PAC).

1455 Old Alabama Road Ste. 100

Roswell, GA 30076 USA

Scaffolding Solutions

Scaffolding components

Service

DISCLAIMER: The information contained in this website is provided by Atlantic Pacific Equipment, LLC (“AT-PAC”) and is for general information purposes only.

© 2025

Atlantic Pacific Equipment (AT-PAC), LLC All Rights Reserved

© 2025

Atlantic Pacific Equipment (AT-PAC), LLC All Rights Reserved