Blog Layout

SCAFFOLDING PARTS AND ACCESSORIES | MAINTENANCE | AT-PAC

December 29, 2019

The efficiency and quality of every construction project depend to a large extent on the equipment you use. We are confident that the scaffolding materials we design and manufacture are among the best in the world, but — like any other piece of equipment on your job site — their long-term functionality requires ongoing inspection and maintenance.

From a safety standpoint, we recommend that all individual scaffolding parts and accessories

are inspected prior to being used, and when the components are returned to the yard, or staging areas. We also recommend that all scaffold assemblies or structures should be inspected and tagged prior to being used, so that the end user can clearly identify what the scaffold is to be used for.

To ensure scaffolding parts and accessories are always maintained for maximum safety follow this 9 step checklist:

- Confirm that all scaffolding components are in place and secure: Wedges, bolts, nuts, spigots… even the smallest component must be present and secure to ensure safety.

- Look for cracks, dents and splits in steel or wooden panels: The floor panels of your scaffolding must bear a lot of weight and withstand heavy objects dropped from above. Even a small weakness in one of these surfaces can spell trouble as these heavy forces are exerted during the job.

- Look for sharp edges: Steel and aluminum often develop burrs and lips, which can lead to cuts and scratches not uncommon to heavy construction work. Noticing and fixing sharp edges is a good step toward preventing infections, bumps, bruises, and even avoiding more serious issues like hospitalization.

- Look for any deflection or bends in equipment (due to overloading): This is especially important at weight-bearing supports and flooring panels that have taken on especially heavy loads. If the metal is already bending under the strain, continued traffic and jarring makes it only a matter of when — not if — it will break.

- Check to ensure nuts on clamps and braces move freely: All scaffolding parts and accessories that are intended to move or be adjustable must be properly lubricated and routinely worked to keep them fully functional. Proper maintenance improves safety and avoids slowdowns during the job.

- Replace all missing/removed spigots with the correct bolt and lock nut: There is no room for cob-jobbing or making do with subpar replacement parts when your workers’ health and safety are on the line. Invest in manufacturer-approved replacement parts only.

- Ensure swing gate springs are functioning: Again, this is a seemingly small and simple maintenance item, but it adds another level of safety at every point in the scaffolding design where a safety barrier exists.

Depending on the size and complexity of your scaffolding, this list could take one safety inspector a few hours to complete. But that investment is well worth the lowered chance of accidents due to faulty or damaged materials.

Contact the professionals at AT-PAC today if you have any questions or concerns regarding properly inspecting and maintaining your existing scaffolding accessories

or ordering replacement parts as needed.

You might also like

AT-PAC Blog

By Julio Black

•

February 17, 2025

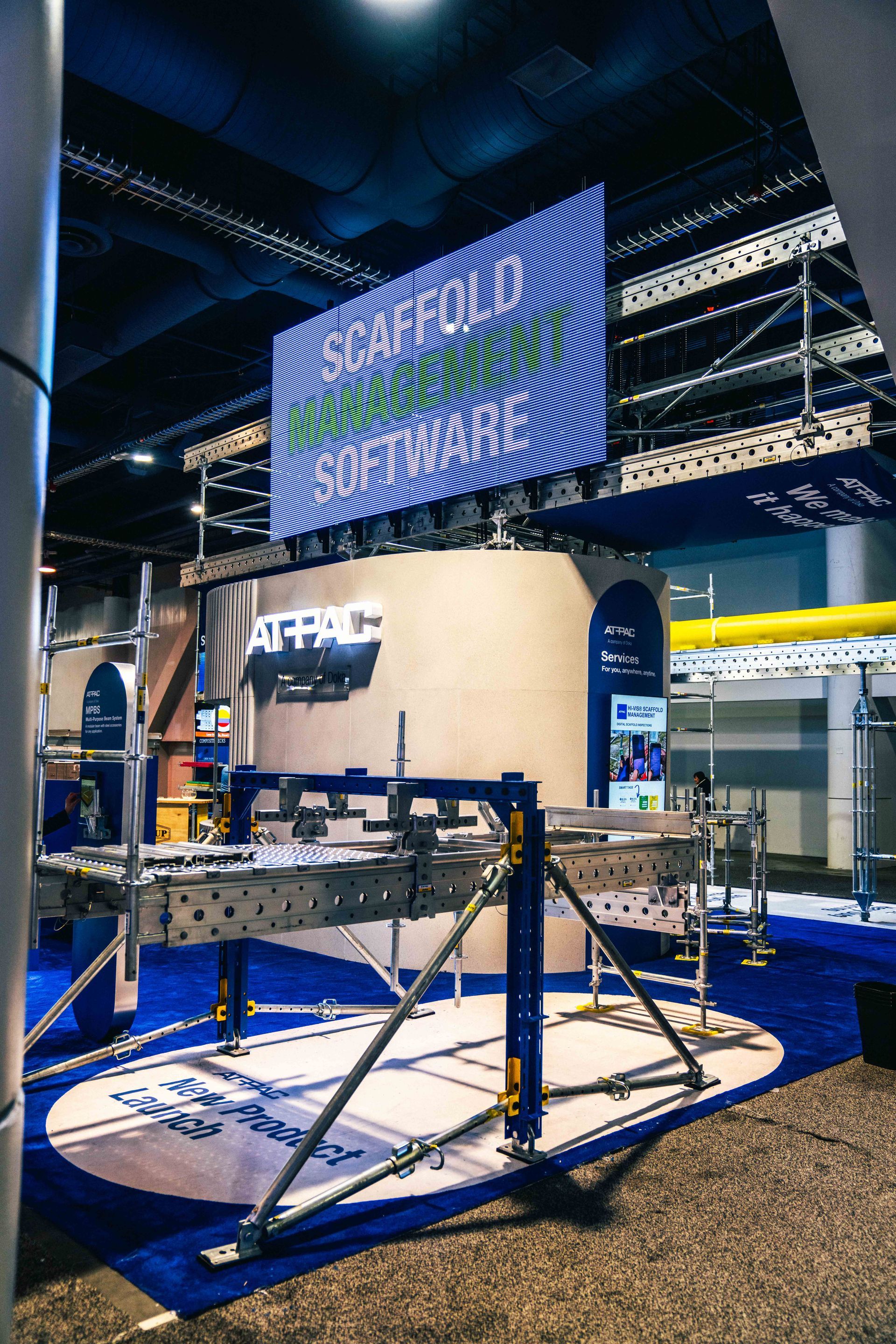

AT-PAC Unveils the Multi-Purpose Beam System (MPBS) at World of Concrete 2024 AT-PAC proudly launched its latest innovation, the Multi-Purpose Beam System (MPBS), at World of Concrete 2024, marking a significant milestone in scaffold technology. As a cutting-edge addition to AT-PAC’s proprietary Ringlock System Scaffold, the MPBS offers unparalleled versatility and efficiency, revolutionizing the way scaffold structures are designed and deployed. A Game-Changer for the Industry Designed to expand the capabilities of the Ringlock System, the MPBS provides a groundbreaking solution for a wide range of applications, including: Suspended Scaffold & Pipe Rack Scaffolds – Enabling safe and efficient suspended access solutions. Birdcages – Creating stable, large-scale work platforms. Large Span Bridging – Allowing for expansive scaffold spans with fewer components. Boiler Scaffolds – Meeting the unique needs of confined and high-heat environments. Cantilevers – Offering extended reach and accessibility. Innovative Design & Seamless Integration The MPBS system is engineered for simplicity and adaptability. At its core is a robust extruded aluminum beam, capable of supporting O-Type Ringlock Planks and an array of attachable steel accessories. With 6-inch (152.4mm) on-center attachment points along its length, the MPBS ensures maximum flexibility, making it suitable for diverse scaffolding applications. What sets the MPBS apart is its seamless integration into the Ringlock System, enhancing functionality while minimizing complexity. The ability to achieve larger spans than traditional methods reduces the overall number of components required, streamlining both installation time and labor costs.

By Julio Black

•

October 11, 2024

Atlanta, Georgia, USA AT-PAC is excited to announce the appointment of Mr. Allan Hazzard as Managing Director Canada. This appointment reinforces AT-PAC’s commitment to strengthening its local management structure to support the continued investment and future growth of our Canadian business. AT-PAC has operated its Canadian branch in Edmonton, Alberta since the year 2000, which has more recently operated alongside the U.S operations under a single North American regional structure. As part of Mr. Hazzard’s appointment, Canada will transition to its own local management structure to further support our recent and anticipated growth into new markets in Eastern & Western Canada. Josh Dundon, CEO shares “The appointment of Mr. Hazzard is a strategic step forward and will enable us to build off the existing talented team and our almost 25-year history in Canada to expand our presence and better service our customers in important markets across Canada”. Based in Calgary, Mr. Hazzard brings over 20 years of leadership experience, including the past decade in the modular building industry with WillScot and contributes a wealth of expertise in scaling businesses across Canada. His executive roles in commercial leadership and general management, both in Canada and the U.S., have equipped him with deep knowledge of asset intensive businesses servicing the industrial & commercial sectors. Mr. Hazzard added “I am truly honored to step into the role of Managing Director for AT-PAC Canada at such an exciting time in the company’s journey. Having spent much of my career in roles focused on scaling businesses across diverse markets, I am thrilled to now lead a talented team in driving AT-PAC’s continued growth and innovation in the Canadian market.” As Managing Director Canada, Mr. Hazzard will be responsible for leading and driving AT-PAC’s next phase of growth in Canada. This includes leading the existing Edmonton based team and implementing our Canada wide strategy ensuring a strong sales, commercial and operational structure to support our customers and continued growth into new markets.

By Julio Black

•

August 28, 2024

AT-PAC, a world leader in the supply of industrial scaffold products, is proud to announce its partnership with Habitat for Humanity. AT-PAC is thrilled to announce their partnership with Habitat for Humanity , a leading non-profit housing organization dedicated to creating and advocating for affordable homeownership. AT-PAC is partnering as a National Sponsor, contributing $100,000 of funding along with strong volunteer support to work towards the goal of affordable homeownership for all. This is a significant step towards enhancing AT-PAC’s corporate social responsibility efforts and will make a tangible impact on the lives of future Habitat homeowners, helping them realize their dream of owning a home and building a brighter future for their families . To kick off this collaboration, AT-PAC has committed to help as a “Roof Raiser” sponsor for Habitat for Humanity’s 2024 Jimmy and Rosalynn Carter Work Project in St. Paul, Minnesota, this October. This event will bring together an estimated 2,500 volunteers, community members, leaders, and future homeowners to build more than 35 new homes in five days! This annual, large-scale building event raises awareness of the critical need for affordable housing — the heart of Habitat’s mission. "This partnership reflects our shared commitment to building a better future, and I am excited about the positive changes we can achieve together" said Josh Dundon, CEO of AT-PAC. In addition, AT-PAC teams in both Atlanta and Houston will be participating in Habitat construction sites in their local communities, building alongside each other and future Habitat owners. Volunteers will see firsthand how affordable homeownership helps families build strength, stability, and self-reliance through shelter. About Habitat for Humanity Driven by the vision that everyone needs a decent place to live, Habitat for Humanity found its earliest inspirations as a grassroots movement on a community farm in South Georgia. Since its founding in 1976, the housing organization has since grown to become a leading global nonprofit working in local communities across all 50 states in the U.S., Puerto Rico, and more than 70 countries. Families and individuals in need of a hand up partner with Habitat for Humanity to build or improve a place they can call home. Habitat homeowners help build their own homes alongside volunteers and pay an affordable mortgage. Through financial support, volunteering or adding a voice to support affordable housing, everyone can help families achieve the strength, stability and self-reliance they need to build better lives for themselves. Through shelter, we empower. To learn more, visit habitat.org.

About AT-PAC

Locations

Careers

GLOBAL HQ

Atlantic Pacific Equipment LLC (AT-PAC).

1455 Old Alabama Road Ste. 100

Roswell, GA 30076 USA

Scaffolding Solutions

Scaffolding components

Service

DISCLAIMER: The information contained in this website is provided by Atlantic Pacific Equipment, LLC (“AT-PAC”) and is for general information purposes only.

© 2025

Atlantic Pacific Equipment (AT-PAC), LLC All Rights Reserved

© 2025

Atlantic Pacific Equipment (AT-PAC), LLC All Rights Reserved